Page 1 of 1

Wired MPG PLC Parameters

Posted: Mon Dec 31, 2018 4:54 pm

by 9wdragline

I added a new MPG to my CNC11 system Can't figure out what to set the plc parameters to.

I'm sure this is an easy fix but I am new to these controls.

Re: Wired MPG PLC Parameters

Posted: Mon Dec 31, 2018 5:38 pm

by cnckeith

hello.

P348 = 15 (15 = tells CNC12 to use on board plug and play MPG encoder port found on the Oak and Allin1DC cnc control boards, as opposed to an MPG plugged into a spare encoder port)

and P350 = 100 (set to 100 steps per rev)

plug in MPG

restart CNC12

move MPG knob from the OFF position to any other position and you are good to go.

Re: Wired MPG PLC Parameters

Posted: Mon Dec 31, 2018 8:15 pm

by 9wdragline

No, You misunderstood my question Keith but thank you for the response.

From what I read in the manual; Parameter 19,40,41,45,46,47 ,128, 129 need to be addressed. Like I said earlier, I am new to this and only have minimal experience on these

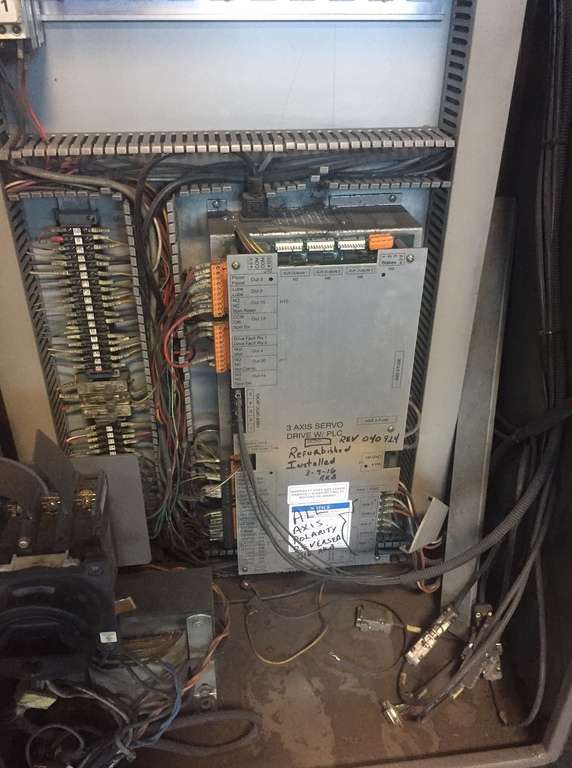

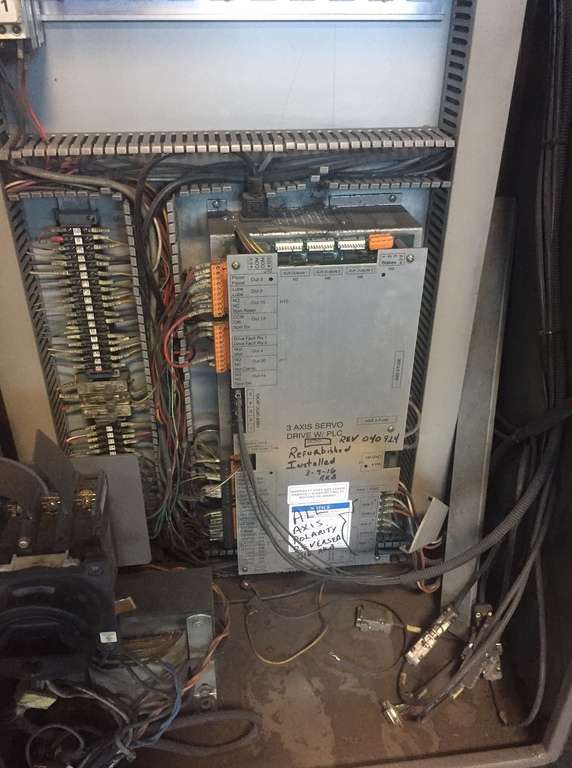

. What I have is the older DC310 CNC11 linux type of control that is on a roughly year 2004 ATrump knee mill. Bought it recently and only have less than 50 or so hours running it.

Re: Wired MPG PLC Parameters

Posted: Tue Jan 01, 2019 11:50 am

by martyscncgarage

Always post a report with your questions. That would have told Keith which control you were running.

You can generate it from the Utility menu.

Marty

Re: Wired MPG PLC Parameters

Posted: Tue Jan 01, 2019 3:53 pm

by cnckeith

ok.. still not sure what you are asking..

what are you trying to achieve? installing an MPG?

p19 is a special feature and you don't want to use that if you are just looking for regular MPG use.

P40 defaults to .0001" and should already be set.

P41 .01 degree is default and should already be set

P45 is not available with your version of software (WCS lockout)

P47?

P129,129 is not available with your version of software (dry run)

Re: Wired MPG PLC Parameters

Posted: Wed Jan 02, 2019 10:36 am

by 9wdragline

Thanks guys! Marty, A report was not necessary. BTW I've watched several of your youtube videos and you have helped me understand these controls better.

The first question asked should have been "Is it plugged in?"

First thing this morning we opened the CPU back cover and Duh the plug on the pigtail from the outer connector on the CPU case wasn't plugged into the keypad board!

The machine's original call of duty was machining carbon fiber using a high speed head mounted in the spindle. We had this thing all apart vacuuming all the carbon fibers out and that plug was overlooked or came off on reassembly.

Keith, I checked the parameters and 40=.0001 and 41 was set to .25 and I reset 41 to .01 like you said was the default.

The MPG works now.

Next question; I checked the hand wheel rotating it one complete turn in the three settings. X1 = .0073'' X10=.0772" X100=.0748" advance

Is something set incorrectly for the X100?

Steve

Re: Wired MPG PLC Parameters

Posted: Wed Jan 02, 2019 11:06 am

by Sportbikeryder

You should probably post the detail about the MPG itself as it may not be the "correct" type for CNC11 on Linux. The report file is always beneficial if one wants to look at it as it will tell those in the "know" pretty much every setting yo have without having to ask you and have you look it up.

Re: Wired MPG PLC Parameters

Posted: Wed Jan 02, 2019 11:43 am

by 9wdragline

Sportbike The MPG came from Centroid.

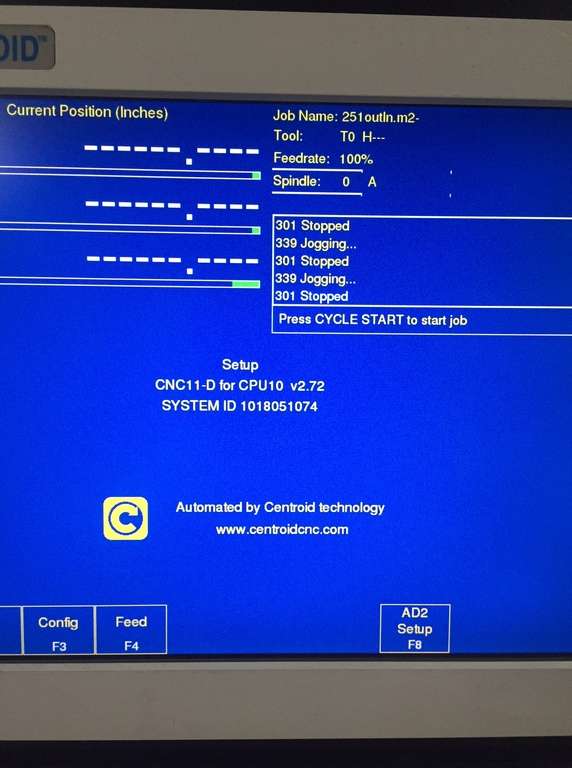

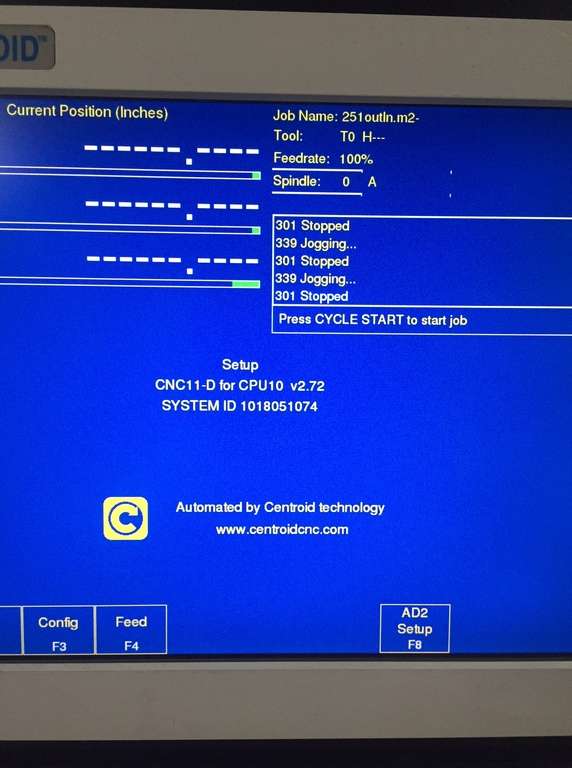

Here's the report

Re: Wired MPG PLC Parameters

Posted: Wed Jan 02, 2019 12:52 pm

by cncsnw

Try turning the wheel no more than three clicks per second (so it takes over 25 seconds to make a full revolution).

Does the axis then go 0.0100" in the x1 increment, and 0.1000" in the x10 increment?

When the wheel is turning "continuously" (and I think the threshold was 3 clicks/second) then the control stops trying to keep up with each individual click, in order to avoid a windup condition which would cause the axis to run on after you stop turning the wheel. The control assumes that moving the exact increment is only important when you are moving one click at a time (e.g., as during a tool touch-off).

Change Parameter 19 to 2 if you want the x100 increment to go full speed.

Re: Wired MPG PLC Parameters

Posted: Wed Jan 02, 2019 1:24 pm

by 9wdragline

cncsnw wrote: ↑Wed Jan 02, 2019 12:52 pm

Try turning the wheel no more than three clicks per second (so it takes over 25 seconds to make a full revolution).

Does the axis then go 0.0100" in the x1 increment, and 0.1000" in the x10 increment?

When the wheel is turning "continuously" (and I think the threshold was 3 clicks/second) then the control stops trying to keep up with each individual click, in order to avoid a windup condition which would cause the axis to run on after you stop turning the wheel. The control assumes that moving the exact increment is only important when you are moving one click at a time (e.g., as during a tool touch-off).

Change Parameter 19 to 2 if you want the x100 increment to go full speed.

That worked. Setting P19 to "2" makes the X100 go full speed. I tried turning slowly then as fast as I could turn it and the movement was only a couple clicks behind. Movement per click is OK x1= .0001" x10=.001" x100=.010"