I was talking to a couple of the Centroid reps last weekend at the Cabin Fever Expo in Lebanon Pennsylvania to see if they could help me.

Very nice guys by the way.

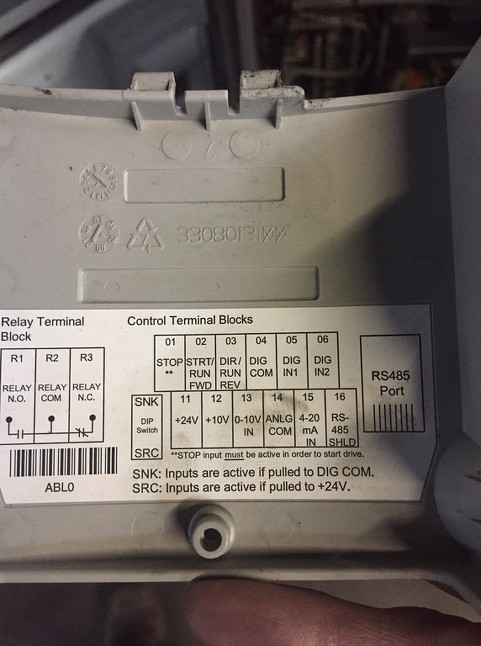

Allen Bradley 22B-B017N104

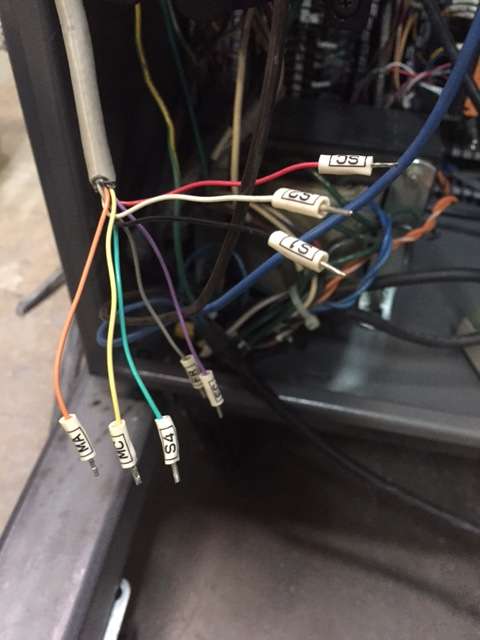

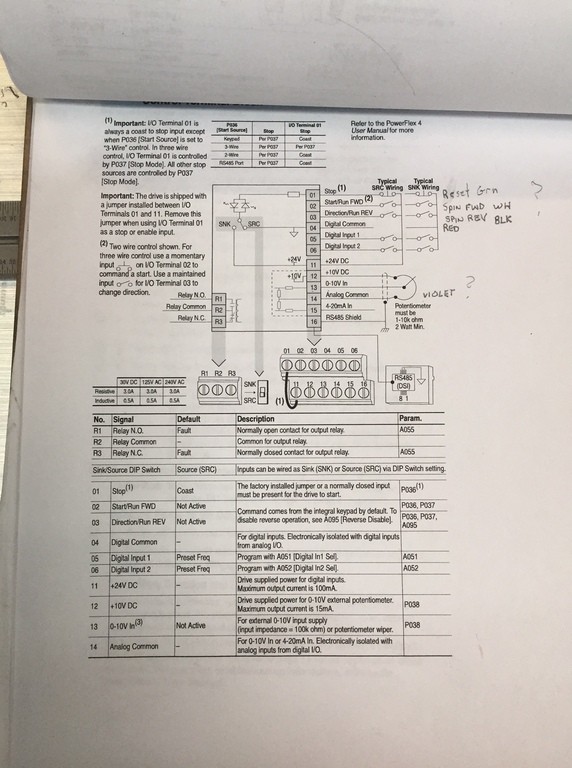

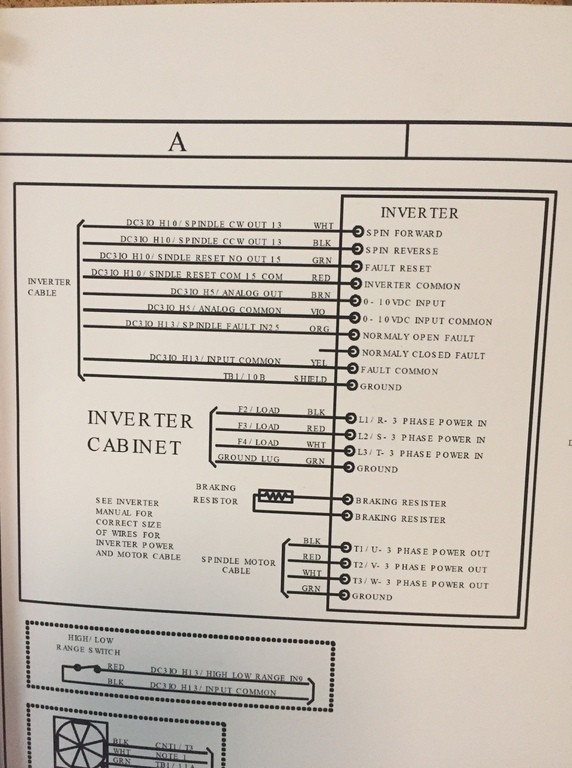

Here is the diagram for the inverter. I penciled in what I think is correct but uncertain where MA MC S4 go.

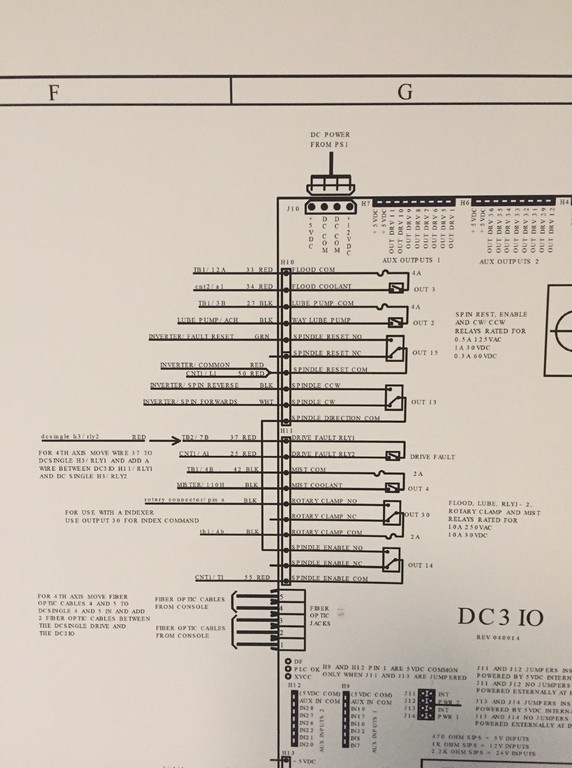

A couple shots from the wiring diagram from Centroid

My control originally had an inverter hooked up but gone when I got it but the wires are there.