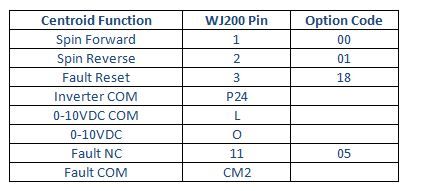

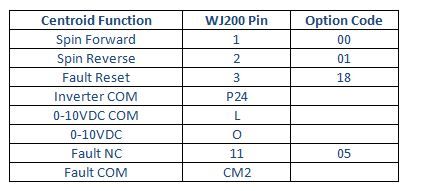

I was reading CM2 on wj200 to inp9-12 on allinonedc and Fault input on allinonedc to 11 on wj200.

Guess I am dense and want a line drawing like the other inverters had LOL.

Moderator: cnckeith

bloomingtonmike wrote:Can we discuss Lube pumps for a minute.

I am confused.

First off my pump only has four wires. Black, White, Green, Red in that order. It is a 110V pump.

I was thinking I would:

run hot/line through the output for Lube (3&4 terminals on top of controller)

Run 110 neutral to the pump

run 24V+ through the pump (in green out red) and into the lube fault input

24V common to the lube fault common bank (cant remember the numbers off hand - either 5-8 or 9-12)

I did that and nothing happened.

Then I ran 24V+ from the 24VDC ps straight into the lube input, completely bypassing the pumps red and green wire, and when I started up everything I got a lube error and the estop tripped.

Tried it again with no 110V or neutral going to the pump at all. Same thing - lube fault error and contactor coil opens.

That really confused me.

Does the lube fault input trip when it sees 24V? I was expecting, since I thought it was expecting the switch to be NC that it wanted 24V+ on that terminal??

I hooked up just 110V to the pump and no conttroller - pump sounds like it is running just fine.

Any advice?

I do not see a name brand on my pump. At this point I am guessing I need to do something else for that lube fault input though.

Mikie