I am ready to start my next retrofit and I have the PC configured and bench tested already and I'm looking for some advice.

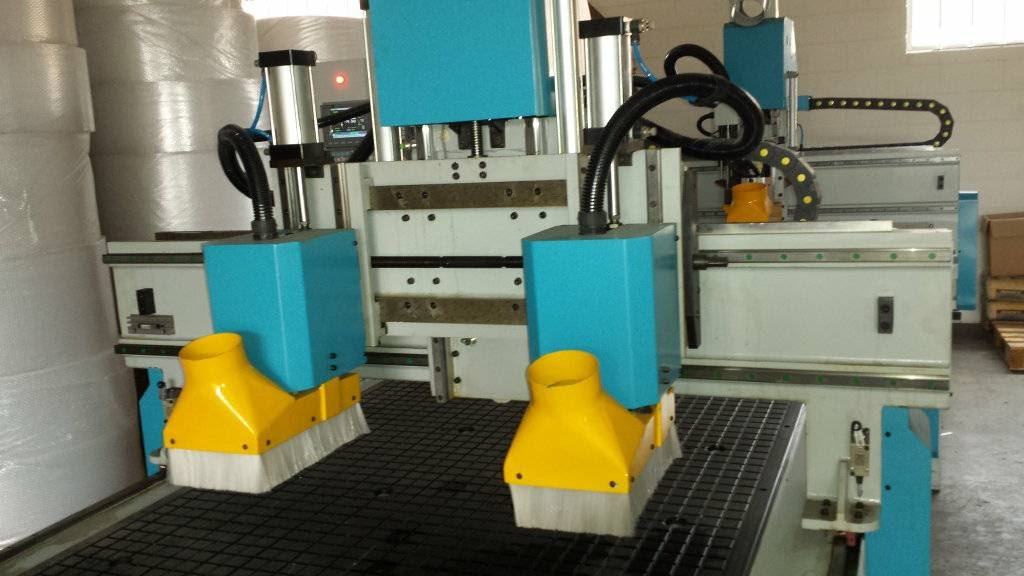

First off, this machine has dual spindles and dual inverters, The space between the spindles is adjustable and each spindle can be retracted independently from Z0.0

As I see it, it's possible to use one spindle for tool 1 and the other spindle for tool 2 if you account for the distance between the spindles, or you can use both spindles in conjunction with each other for machining the same part simultaneously if you can get the tool length to be the same. I imagine that there is some adjustable hard stop on the spindle which will make this a fairly easy adjustment, but I haven't looked into it yet.

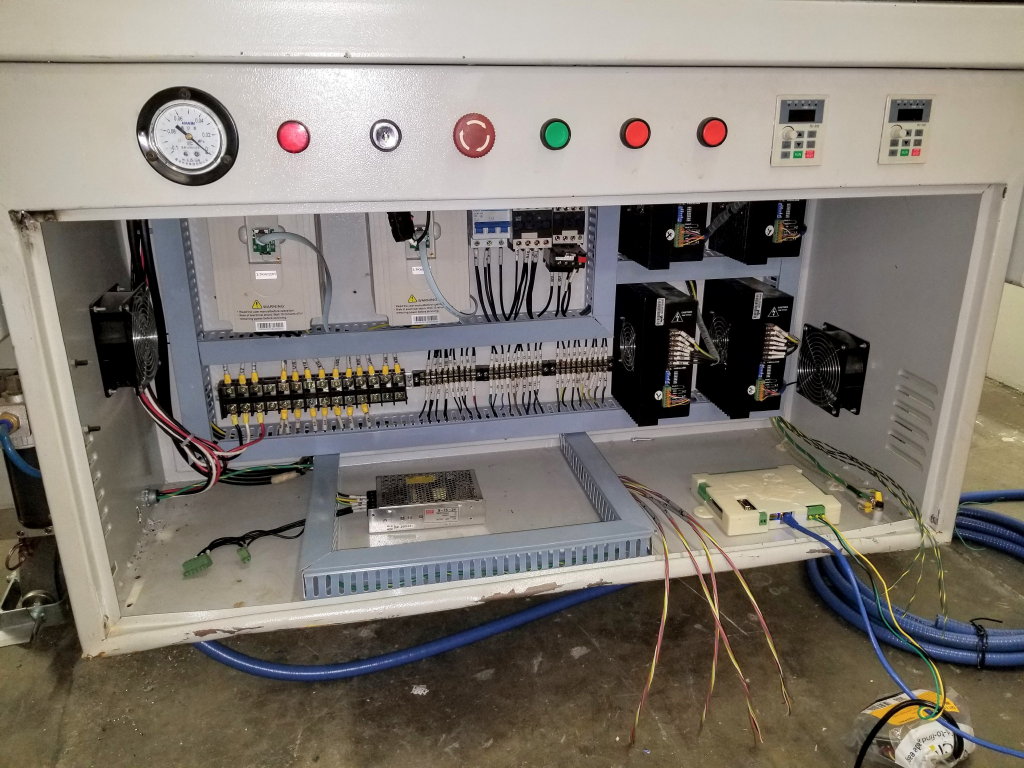

Currently, the spindle on off and speed is controlled independently from VFD operator panels mounted on the front of the machine and spindle engaged or disengaged (spindle up or down) is currently controlled by an air valve turned on and off with a button from the control panel. having acorn control both spindles independently would be nice, but there is only one DAC and limited i/o but I'm sure there is some way to make this happen, but maybe it's not worth it?

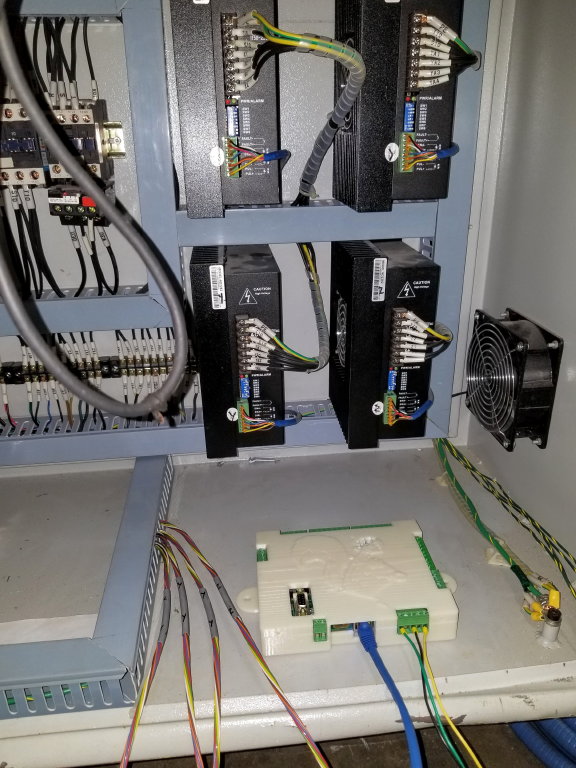

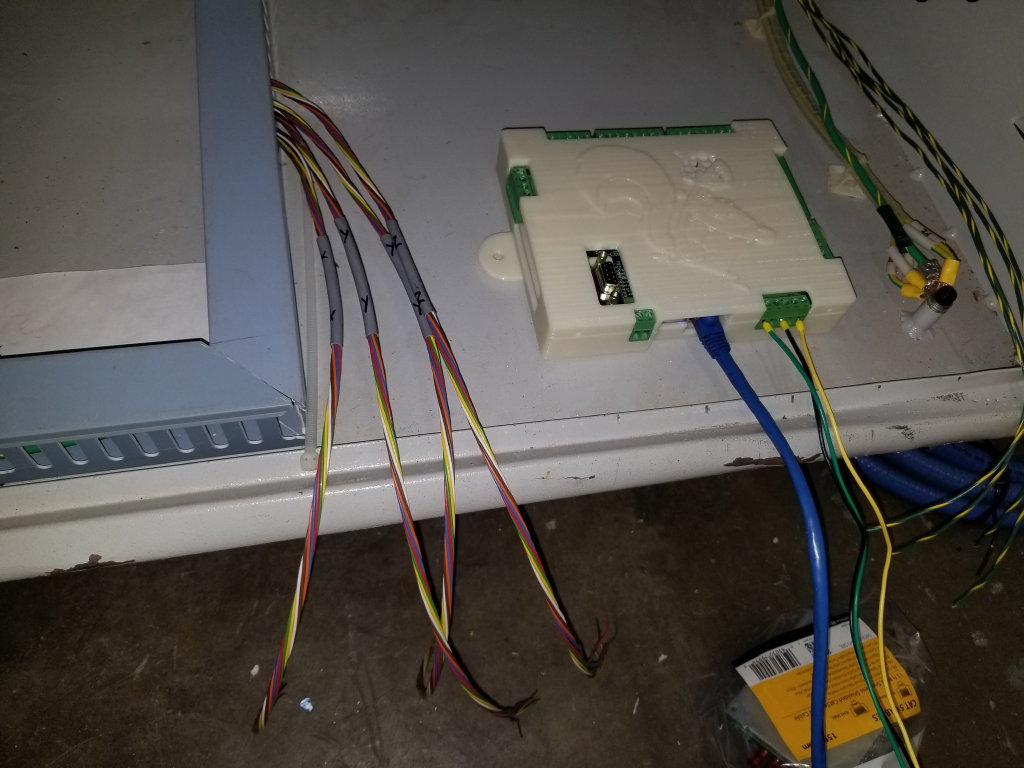

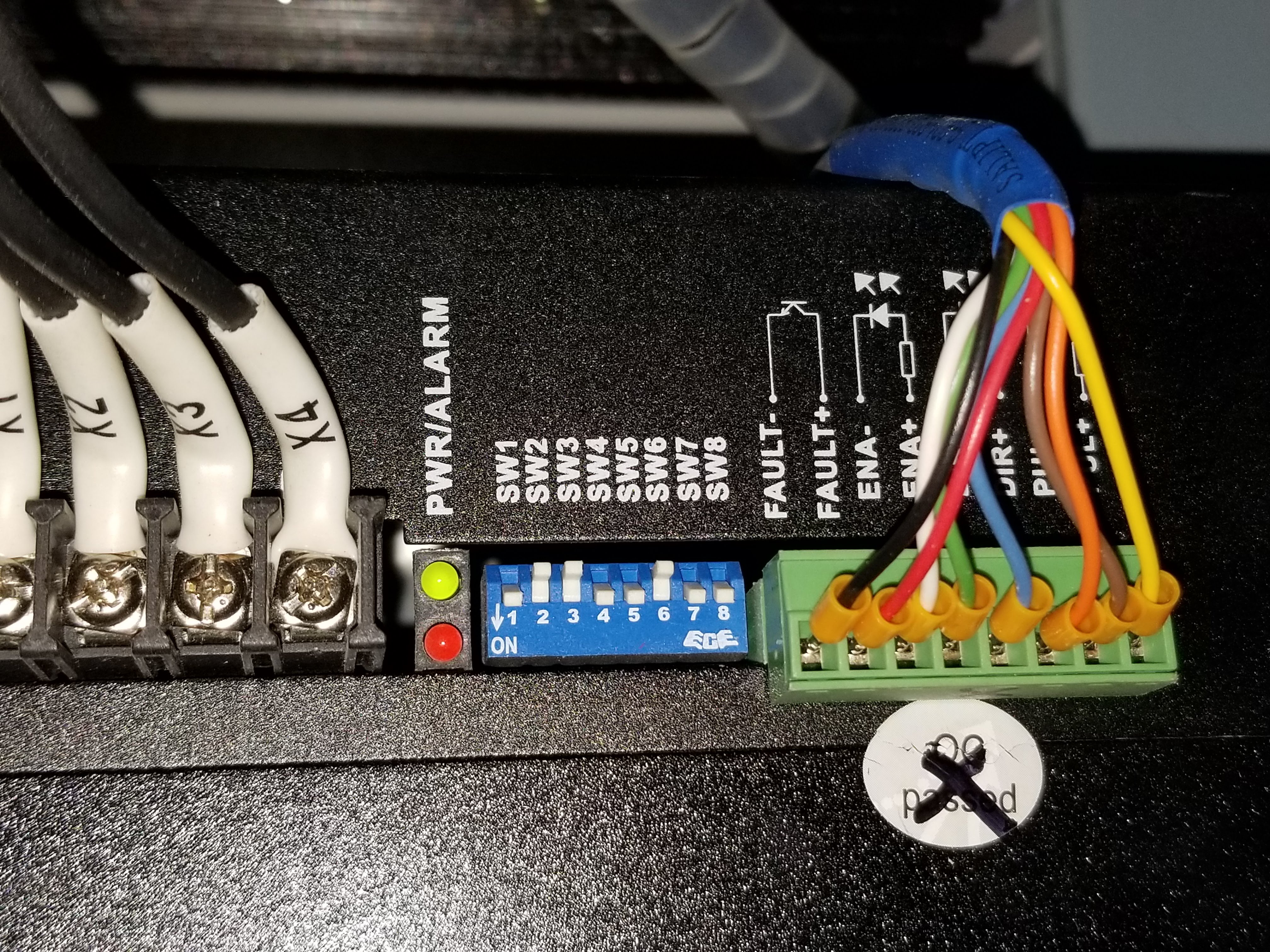

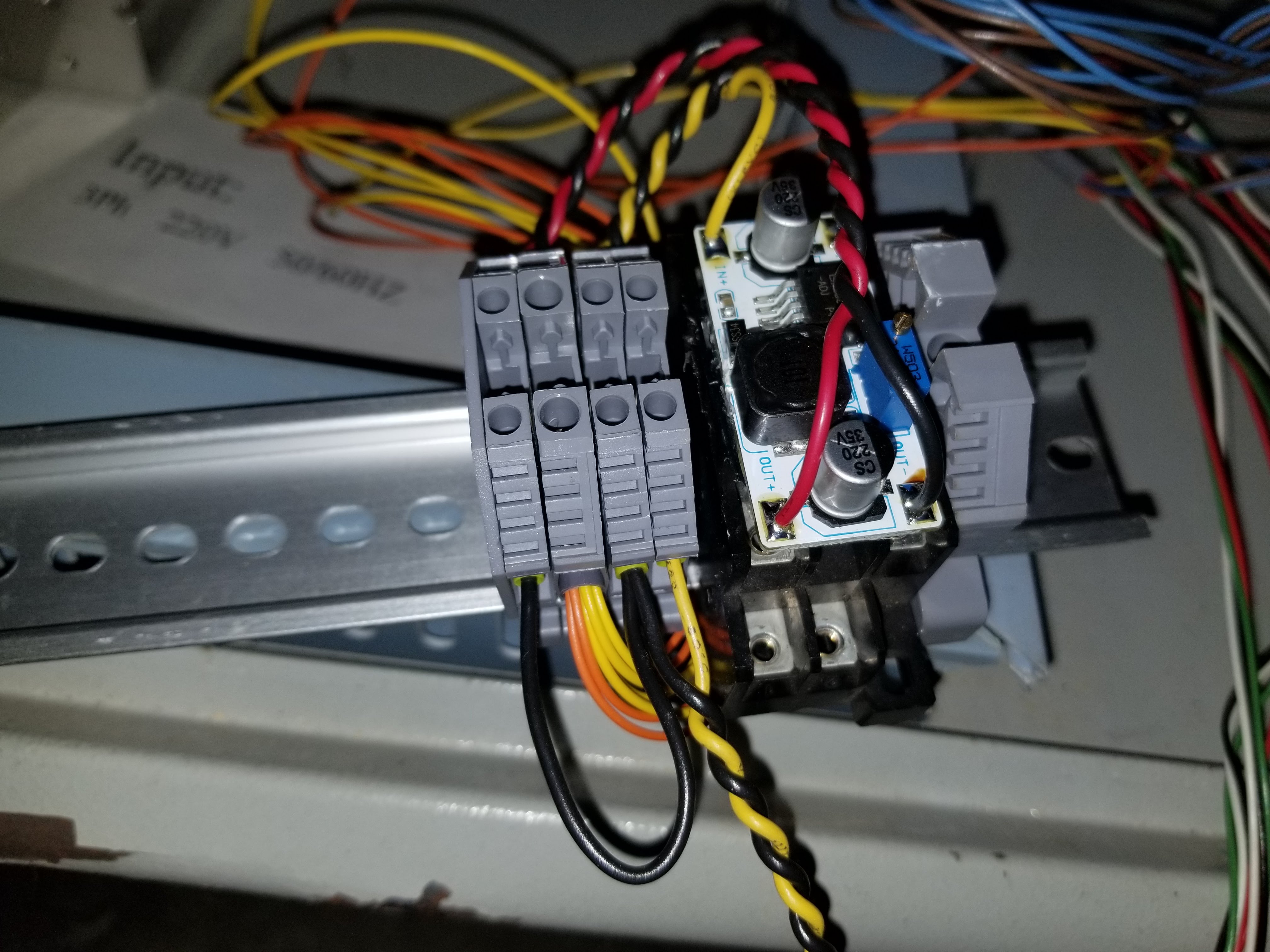

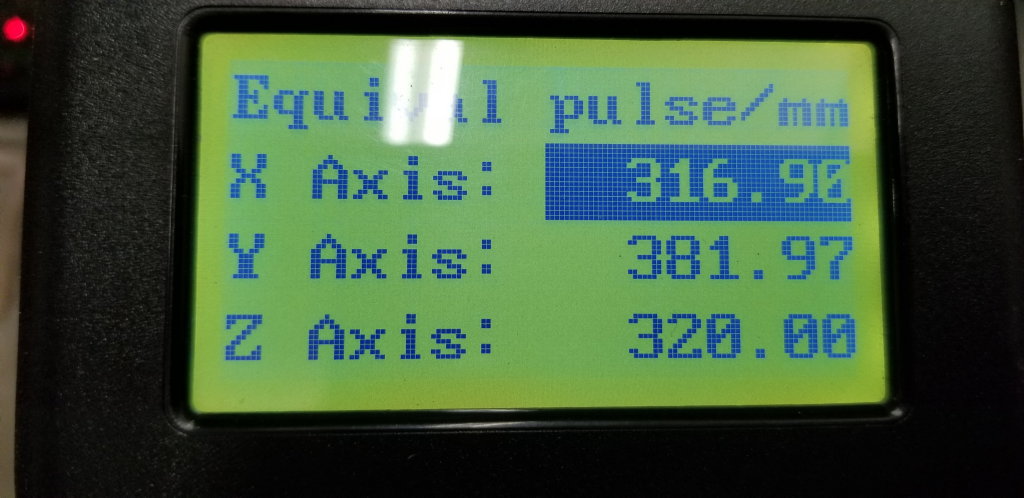

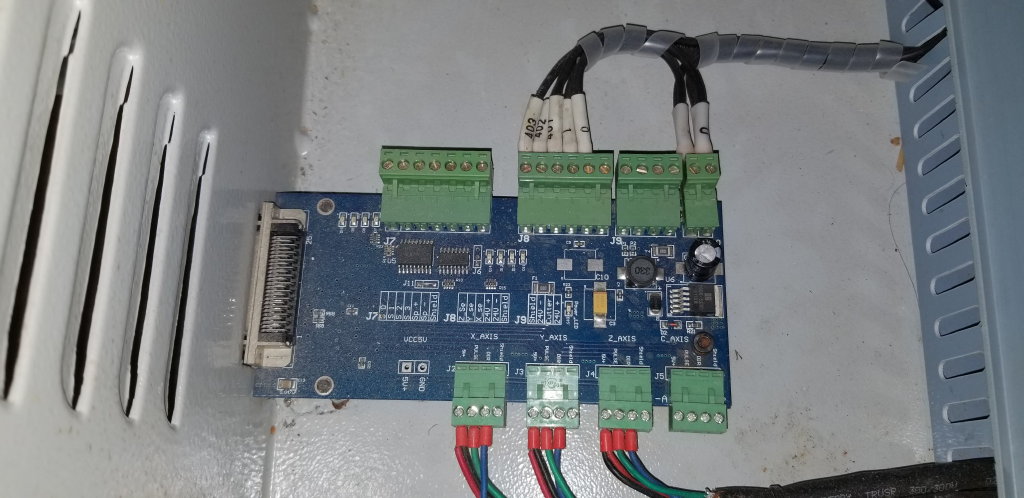

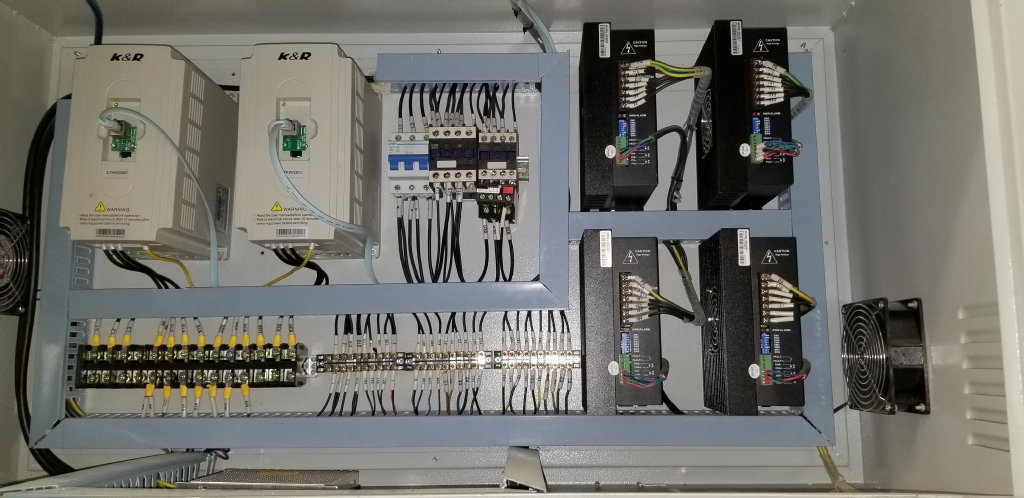

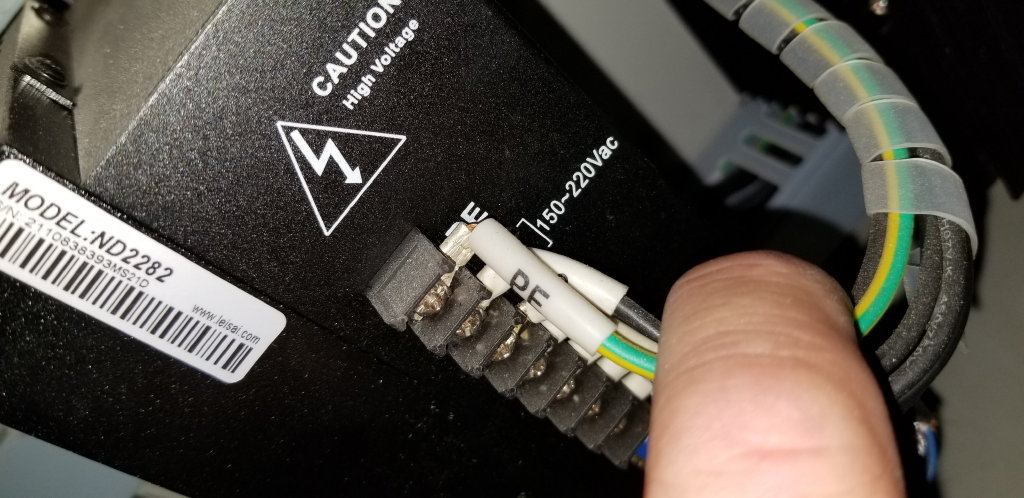

The machine uses Leadshine motors and drives. I do not have a photo of the stepper motors at this time, but have many photos of the drive cabinet:

Currently, there are 2 motors on the gantry and the input to the drives are wired in parallel. I have the pro software so I intend on using the axis pairing to drive the dual motors.

One of the things I question is whether down the road I will miss having a 4th axis on the machine vs having the ease of gantry squaring via the homing routine. What have others done in this situation? How well does parallelling the dual drivers work? What does the squaring routine look like for parallel driven drivers? Can the axis be squared up and locked into position and then power up the drivers?

Maybe I just do the minimum amount of work to get the Acorn running in place of the Rich Auto DSP control and install some dial indicators on the gantry and see whats going on with it during homing and return to zero and then move on from there?

I'm also looking for input on whether to wire the existing controllers to the DB25 (no need for a 5 volt supply) or use the open collector outputs? I like using the DB25 as its a really clean way to make the connections, but then so are the phoenix connectors!

I have another router machine that only has one Yaskawa servo on the gantry and its dual rack and pinion drive via what looks to be about a 1 1/8" drive shaft running across the gantry. Not sure how well this situation works either, I cannot feel any play on either side of the rack and pinion. As the system wears, I'm sure the resulting error gets larger. I have not used either of these machines up to this point. I hope to replace the existing Syntec control with the acorn if the linear tool changer can be accommodated but that will be the subject of a different thread!