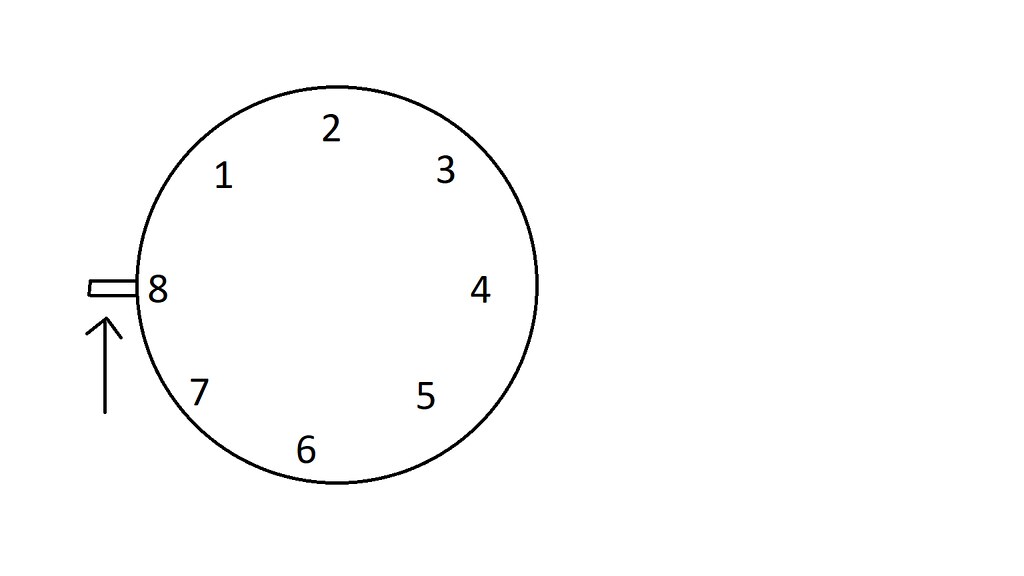

The turret rotates clockwise, facing the numbers as per the image. So to get from tool 8 to 7, the following logic applies:-

IF #5023 > #4120 THEN #101 = #4120

G53 A[#101]

Which in this case = G53 A7. correct?

Agreed?

So lets use an example. I have tool 8 set, Centroid confirms T0808. To move to tool 7, I rotate clockwise, 45 degrees (marked as 1 however based on your ratio of needing to satisfy this condition.

; Notes: Turns/rev must be configured 1 = 1 turret position change

In other words, you are calling turret position 1, to be A1, 2, at A2 and so forth. Correct?

So if I wanted to from 8 to 4, I simply move 4 clockwise, using the same code.

IF #5023 > #4120 THEN #101 = #4120

G53 A[#101]

Which in this case = G53 A4. correct?

Assuming that's all correct, the logic to go the other way is more difficult due to the one way system of the ratchet.

Ive just found a flaw in my calcs, as I was trying to do the movement calculation. I now understand why your numbers were so high, as you have to go past the max turret number .... makes sense now.

However, to me, this doesnt seem to work as I have a number system that decreases. The only logic I can see is the following.

If I want to go from 1 to 8, I simply need to issue a command G53 A0, correct? This takes me from A1 to A0 which also happens to be 8 as there are 8 turret positions.

Another example, I want to go from 5 to 7, I use G53 A-1, correct?

This means that the logic looks to be:-

IF #4120 > #5023 THEN #101 = #4120 - #100, correct?

Ill try this tomorrow, I'm certain this should work unless ive misunderstood this.

Thanks